Shin-Etsu Vietnam saves over VND 5 billion per year through RECP implementation

By implementing Resource Efficiency and Cleaner Production (RECP) solutions – from simple technical adjustments to larger-scale investments Shin-Etsu Magnetic Materials Vietnam Co., Ltd. (100% Japanese-owned, located in Deep C Industrial Park, Hai Phong) has saved more than VND 5 billion per year and reduced over 2,000 tons of CO₂ emissions, becoming one of the exemplary enterprises applying the Eco-Industrial Park (EIP) model in Vietnam.

A large-scale enterprise in rare-earth magnet manufacturing

Established in 2011 with a total investment of nearly USD 450 million, Shin-Etsu Vietnam currently operates three factories on an area of more than 200,000 m² and employs 2,159 workers.

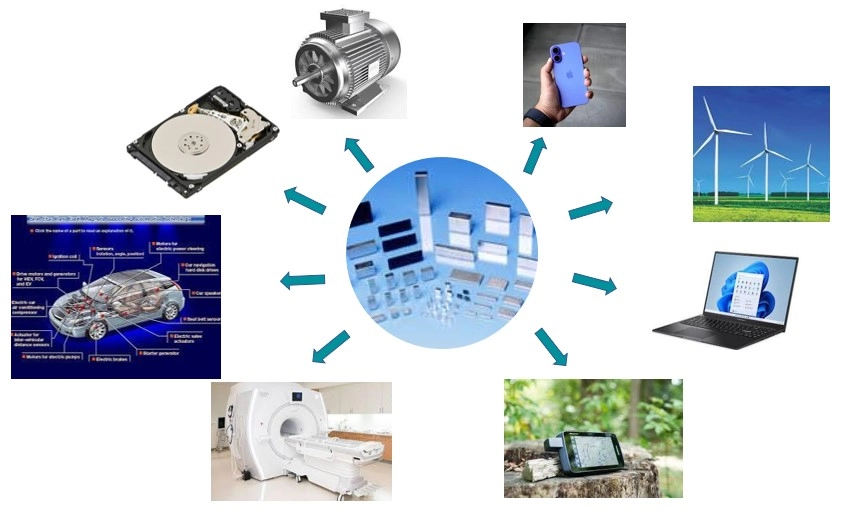

The company specializes in producing rare-earth magnets – an essential material used in various industries such as motors, automobiles, electronics, wind energy, and healthcare.

Products of Shin-Etsu Vietnam and their applications in daily life.

From initial skepticism to breakthrough transformation

In 2022, when the project “Implementing EIPs in Vietnam through the approach of the global EIP programme”, funded by the Swiss State Secretariat for Economic Affairs (SECO) and implemented by UNIDO in cooperation with the Ministry of Planning and Investment, invited Shin-Etsu to participate, the Japanese leadership believed the factory had already been optimized according to Kaizen principles for many years and that few further improvements were possible.

According to Ms. Nguyen Thi Lien, in charge of Environment – Health – Safety (EHS, HOS), it took more than two months of persuasion before the company agreed to allow the expert team to conduct a highly restricted assessment.

Ms. Nguyen Thi Liên shared at the Sustainable Production Expert Training Course organized by the Ministry of Industry and Trade in Quang Ninh, November 2025.

However, after only three days of on-site assessment, the working team led by expert Đinh Mạnh Thắng (VNCPC) identified 21 feasible saving opportunities related to electricity, water use, and internal management.

Savings surpassing all expectations

- In 2022 alone, Shin-Etsu implemented 19 out of 21 solutions with a total investment of USD 200,520.

The results were remarkable: - USD 257,000 saved annually (equivalent to over VND 5 billion)

- 2,031 tons of CO₂ emissions reduced

Improved working conditions and operational performance

- Many solutions were simple yet highly effective, such as:

- Setting air conditioners to 26°C

- Strengthening industrial maintenance: repairing steam trap leaks, cleaning air compressor filters, air-conditioning filters, etc.

- Ventilating the compressor room

- Adjusting water flow in hand-washing areas

According to Ms. Liên, “Small improvements brought results far beyond expectations. They also helped the company meet the strict environmental standards required by EU and U.S. customers.”

Continued strong investment driven by confidence in improvement results

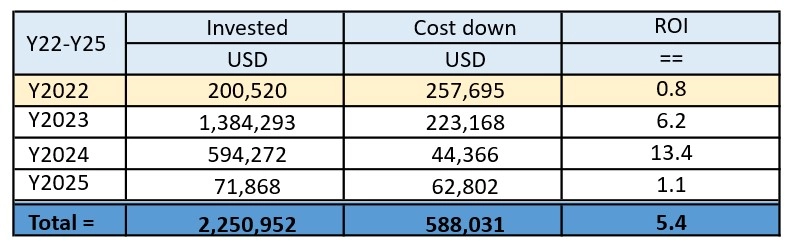

From 2023 to 2025, Shin-Etsu Vietnam continued investing more than USD 2 million in RECP solutions.

In 2023 alone, nearly USD 1.4 million was spent on new machinery and equipment, including four air compressors. These investments are considered to have high returns on investment (ROI) and significantly enhance production efficiency.

Investment and cost savings at Shin-Etsu over the years through RECP implementation.

During this period, Shin-Etsu Vietnam also implemented 35 additional RECP solutions, further optimizing the entire production line.

The company’s success demonstrates clearly that RECP not only protects the environment but also delivers tangible economic value to businesses.

The EIP Project – A launchpad for sustainable production in Vietnam

The project “Implementing Eco-Industrial Parks in Vietnam Through the Approach of the Global EIP Programme” (2020–2024), funded by SECO and implemented by UNIDO and the Ministry of Planning and Investment, aims to:

Enhance productivity and resource efficiency

Improve economic – social – environmental performance of enterprises

Contribute to promoting sustainable production in Vietnam

Deep C Industrial Park, Amata Industrial Park, and more than 100 participating enterprises have reported many positive outcomes.

VNCPC